General Contractor

Acadiana, Louisiana

Building Across Cajun Country

August 2021 brought Hurricane Ida screaming through Acadiana with 150 mph winds. From Abbeville to Opelousas, roofs peeled back like sardine cans. In New Iberia, entire streets went dark for two weeks. We had crews working dawn to dusk across six parishes, and what we saw confirmed what three generations of building in South Louisiana taught us: construction here requires different thinking than anywhere else in America.

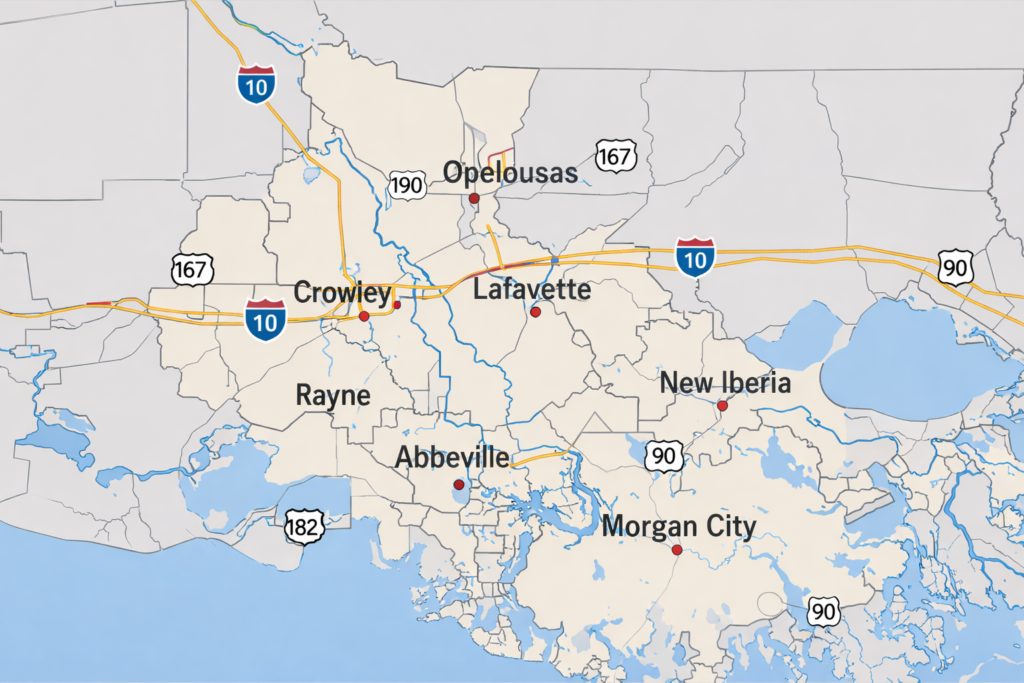

The Acadiana region sits in a unique spot. You’ve got coastal parishes like Vermilion dealing with storm surge, prairie towns like Rayne and Crowley fighting expansive clay soil, and northern communities like Eunice, where proper drainage means the difference between a dry home and a flooded one. Then there’s the Atchafalaya Basin influence, moisture hangs in the air, wood rots fast, and metal rusts if you pick the wrong coating.

As a general contractor serving Lafayette, New Iberia, Broussard, Youngsville, Carencro, Scott, Rayne, Crowley, Opelousas, Eunice, Abbeville, and everywhere between, we’ve learned that cookie-cutter approaches fail. What works on a slab foundation in Scott might flood in low-lying Breaux Bridge. A fence that stands twenty years in Carencro will rot in three if you use the same wood near Vermilion Bay.

People ask why we focus exclusively on Acadiana. Simple, this place is different. The soil shifts. The storms hit hard. The humidity never quits. You need someone who knows that cypress weathers better than pine, that certain concrete mixes crack less in our clay, and that your roof better be rated for Zone 2 wind speeds or you’re replacing it after the next big blow.

Water Damage Restoration Service

September through November used to be our slow season. Not anymore. Between hurricanes, tropical storms, and what locals call “come a cloud” afternoon deluges, water damage restoration runs year-round now.

Three calls stick out from last year. A home in New Iberia flooded after afternoon thunderstorms dumped six inches in two hours. The builder used standard drywall in the garage, which wicked moisture up the walls into the living spaces. A century-old home in downtown Opelousas had water pouring through light fixtures after straight-line winds tore sections of its roof away. And a newer build in Abbeville got hit twice in one season because nobody addressed the drainage issues before building.

Emergency water extraction starts the moment you call. We run truck-mounted pumps that remove standing water faster than shop vacs and box fans ever could. The first 24 hours matter most—drywall begins to break down, mold spores activate, and wood framing begins to swell. Our industrial dehumidifiers pull moisture from the air, while air movers circulate it to speed drying.

Mold remediation follows a protocol. We test first, identify the species, then contain the work area with negative air pressure so spores don’t spread to clean parts of your house. HEPA filtration runs constantly during removal. We strip affected materials, treat surfaces with antimicrobial solutions, then verify clearance before rebuilding.

Storm damage repair means different things depending on when we arrive. Sometimes it’s emergency board-up and roof tarping to stop additional water intrusion while we wait for adjusters. Other times, it’s full reconstruction after insurance settles. We work with every major carrier operating in Acadiana and know their documentation requirements.

Humidity control goes beyond the initial emergency. Many homes in Acadiana have chronic moisture issues due to poor ventilation, inadequate insulation, or drainage problems. We install vapor barriers in crawl spaces, upgrade bathroom and kitchen exhaust systems, and fix grading issues that direct water toward foundations instead of away.

Roofing Contractor

Metal roofs started appearing across Acadiana after Hurricane Rita in 2005. Homeowners in Crowley, Rayne, and Eunice watched their neighbors’ shingle roofs fail and decided that standing-seam metal made more sense in the long term.

They were right. A properly installed metal roof laughs at wind. We’ve inspected metal roofs after storms that stripped every shingle roof within sight, not a panel out of place. They cost more up front, but the math works out when you factor in longevity and insurance discounts.

Shingle roofs still dominate Acadiana, though. Three-tab shingles are builder-grade and don’t survive here. We install architectural shingles rated for 130 mph winds, preferably higher. The underlayment matters as much as the shingles themselves—we use synthetic underlayment that won’t rot if moisture gets under the shingles.

Hurricane-resistant installation means more than just slapping shingles down with a nail gun. We use six nails per shingle instead of four. Ring shank nails hold better in wind uplift. Ice and water shield goes in valleys and along eaves. Ridge venting gets properly baffled so wind-driven rain can’t enter.

Roof repair after storm damage starts with assessment. Sometimes you can repair sections. Other times, the damage is too widespread, and replacement makes more sense. We photograph everything for insurance documentation and provide detailed estimates that break down materials and labor.

Ventilation deserves more attention than it gets in Acadiana. Attics routinely hit 140 degrees in summer. Without proper intake and exhaust venting, that heat transfers into living spaces, and your AC runs constantly. Ridge vents combined with soffit vents create convection that pulls hot air out naturally.

Insurance claim assistance isn’t something we advertise heavily, but it’s part of what we do. We meet with adjusters, walk them through damage, and advocate for proper repairs. Some adjusters’ lowball estimates or miss secondary damage. Having someone who knows construction and insurance language helps get fair settlements.

Fence Contractor

Termites and rot kill more fences in Acadiana than wind. We replaced a beautiful cedar fence in Carencro last year, a seven-year-old fence that was already collapsing because the posts weren’t treated and were in direct ground contact. The homeowner was furious that they’d spent good money on something that didn’t last a decade.

Vinyl and composite fencing solve the rot issue. It won’t win beauty contests against a freshly stained wood fence, but fifteen years later, when the wood fence is gray and splitting, the vinyl still looks like installation day. We install vinyl with aluminum reinforcement in the rails—straight vinyl can sag and warp in our heat.

Wood privacy fencing still gets requested, especially in established neighborhoods like the Garden District in New Iberia or older sections of Lafayette, where everyone has traditional wood fences. We use pressure-treated southern yellow pine for the structure and either pressure-treated southern yellow pine or cedar for the pickets. The posts go in concrete, a minimum of three feet deep, with gravel at the bottom for drainage.

Hurricane-rated installation means setting posts deeper and using through-bolts instead of screws for rail attachment. We learned this the hard way—regular fences become missiles in 100+ mph winds. Newer subdivisions in Youngsville and Broussard often require engineered fence systems capable of withstanding specific wind loads.

Aluminum and wrought iron work well for decorative applications. Front yards, pool enclosures, and commercial properties often choose metal because it’s low-maintenance and lasts. The powder coating matters; cheap coating flakes off in our humidity. We use marine-grade coatings that resist salt air near the coast and handle moisture inland.

Chain link still has a place, particularly for large properties, commercial applications, and back pastures. Vinyl-coated chain link costs more but doesn’t rust like galvanized chain link. For farm fencing around Rayne, Crowley, and Eunice, we install four-foot woven wire with treated posts set in concrete.

Concrete Contractor

The soil across Acadiana moves. Much of the region sits on heavy clay soils that swell when wet and shrink when dry. New Iberia has expansive clay zones that shift with changes in moisture. Abbeville, near the coast, has sandy soils that drain quickly but offer poor bearing capacity.

Concrete slab foundations need proper engineering for local conditions. We excavate and compact properly, install vapor barriers, and use fiber-reinforced concrete that resists cracking from soil movement. Control joints get cut in specific patterns to direct cracking to predetermined locations.

A concrete contractor in Scott called us last year to look at a slab job gone wrong—massive cracks within six months of pouring. They’d skipped soil testing, didn’t compact the fill, and poured on a rainy day. The concrete itself was fine. Everything under it was wrong. We ended up demo’ing and starting over.

Decorative stamped concrete driveways and patios look great, but require different prep than structural slabs. Proper drainage is critical—standing water on stamped concrete leads to staining and eventual surface breakdown. We slope everything away from structures and install drains where water naturally collects.

The mix design varies by application. High-early-strength concrete is well-suited to quick-turnaround projects. We add plasticizers for better workability in hot weather. Air entrainment helps concrete withstand freeze-thaw cycles, though we don’t get many here this far south.

Sidewalk and driveway installation follows similar principles. A minimum of four inches thick for driveways; six inches in areas with heavy vehicle traffic. Wire mesh or fiber reinforcement controls cracking. Expansion joints every ten feet allow for movement without cracking.

Repairs often cost more than people expect because you can’t just slap new concrete on top of old concrete. We remove damaged sections completely, prep the edges properly, and tie new concrete into the existing with rebar dowels. Half-measures fail within a year.

Gutter Installation Contractor

In May 2021, twelve inches of rain fell on Acadiana in three days. Streets flooded, yards became ponds, and houses without proper gutter systems suffered foundation damage, flooded crawl spaces, and eroded landscaping.

Seamless aluminum gutters handle our rainfall better than sectional gutters. No seams means fewer leak points. We size gutters based on roof area and rainfall intensity—standard five-inch gutters work for most homes, but larger roofs or steep pitches need six-inch gutters and larger downspouts.

Gutter guards are almost mandatory in Acadiana. Live oaks drop leaves year-round. Sweet gums drop those spiky seed balls. Pine needles mat together, blocking downspouts. We install micro-mesh guards that keep debris out while allowing water through.

The slope matters more than people realize. Too flat, with water sitting in the gutters, breeding mosquitoes, and eventually rusting through the aluminum. Too steep and water overshoots at the downspouts during heavy rain. We aim for a quarter-inch drop per ten feet of run.

Downspout placement and extension determine whether gutters actually protect your foundation. Water must discharge at least six feet from the foundation, and farther if your lot slopes toward the house. We use solid PVC extensions buried underground when surface extensions interfere with landscaping or mowing.

A home in Eunice called us because their crawl space was constantly flooded despite having gutters. The gutters had proper slope and were clean, but the downspouts dumped right at the foundation line. We extended the downspouts and added a couple of surface drains in low spots. Problem solved.

Commercial gutter systems for metal buildings and large structures require different engineering considerations. We calculate watershed capacity, account for overflow during extreme events, and install industrial-sized gutters and downspouts that won’t overflow during the kind of cloudbursts Acadiana sees every summer.

Outdoor Living Contractor

Nobody spends much time outside in Acadiana between May and September unless they’re fishing or hunting. Too hot, too humid, too many mosquitoes. But spring and fall are gorgeous, and a well-designed outdoor living space extends your usable square footage for six months a year.

Covered patios are the foundation of Acadiana outdoor living. Direct sun is brutal. Rain comes frequently. A roof over your patio lets you grill during a thunderstorm and sit outside on summer evenings once the sun sets and temperatures are tolerable.

We built a massive covered patio in Youngsville last fall—twenty by thirty feet, all cypress with a standing seam metal roof. The homeowner wanted to enjoy the view of their pond without getting rained on or sunburned. We added motorized screens that drop down to block wind and bugs. It’s basically an outdoor room.

Outdoor kitchens need to withstand the weather. We use marine-grade stainless steel for grills and burners, weather-resistant polymer cabinetry, and granite or concrete countertops. Regular kitchen cabinets rot. Standard refrigerators rust. Everything needs to be rated for outdoor use.

Deck building in Acadiana works best with composite materials. Wood decks look great for three years, after which they require constant staining and sealing to prevent rot. Composite costs more up front but won’t rot, splinter, or require refinishing. We use hidden fastener systems for a clean appearance.

A composite deck in New Iberia that we built five years ago still looks new. The wood deck next door is already showing rot at the posts and has areas of splintered boards. The neighbor mentioned they wished they’d spent the extra money on composite.

Pergolas add shade and vertical interest. We build them from treated lumber, cypress, or cedar, depending on budget and desired look. They won’t keep rain off—they’re more about filtered sun and creating defined outdoor spaces. Adding climbing plants like jasmine or wisteria softens the look and adds fragrance.

Fire pits and outdoor fireplaces extend the outdoor season into winter. Gas fire pits are convenient and clean. Wood-burning fire pits and fireplaces create ambiance but require more maintenance and need to be positioned away from structures.

Siding Contractor

Fiber cement siding has become the default choice for new construction and re-siding projects across Acadiana. It won’t rot like wood, won’t melt like vinyl, resists termites, and holds paint longer than anything else.

We re-sided a home in Abbeville two years ago that had original 1970s wood siding. Rot everywhere, paint peeling, gaps big enough to see through. The homeowner had been painting every three years and was still losing ground. We stripped everything to the studs, added house wrap and foam insulation, and then installed fiber-cement lap siding. They won’t need to paint for fifteen years.

Vinyl siding gets a bad reputation, some deserved. Cheap vinyl warps in heat and cracks when hit. Quality vinyl with proper backing and insulation works fine in Acadiana. The key is ventilation: vinyl needs to breathe; otherwise, moisture gets trapped behind it and rots the sheathing.

Wood siding still appears on historic homes and on homes where homeowners want a traditional appearance. We use cedar, cypress, or pressure-treated pine depending on exposure and budget. Proper installation includes house wrap, furring strips for ventilation, and back-priming all boards before installation.

Mildew-resistant treatments and paints are mandatory in Acadiana. Regular paint fails within two years. We use paints with mildewcides and apply them on properly prepared, dry surfaces. Painting during humid summer months invites failure—the paint never fully cures, and mildew colonizes immediately.

Moisture control behind siding matters more than the siding itself. We install house wrap or building paper properly, flash all penetrations, and create a rain-screen gap between the siding and sheathing. This allows any moisture that gets behind the siding to dry out instead of rotting your walls.

Metal Buildings Contractor

Metal buildings dominate commercial and agricultural construction across Acadiana. Drive through Rayne, Crowley, or Eunice, and you’ll see them everywhere: equipment storage, workshops, rice drying facilities, and warehouse space.

Pre-engineered metal buildings go up fast and cost less than stick-built structures. We can erect a 30×40 workshop in a week. The same building, in wood-frame construction, takes a month to build. Metal buildings also resist hurricanes better than wood structures when properly anchored.

A farmer near Crowley needed a shop for his rice farming operation. We built a 60×80 metal building with 16-foot sidewalls, insulation, LED lighting, and three overhead doors. He stores combines, tractors, and equipment worth more than most houses. The building cost a fraction of what conventional construction would have run.

Metal carports and equipment shelters make sense for Acadiana weather. Vehicles and equipment left in the sun deteriorate fast. A metal carport with a roof provides protection from the sun and rain at a reasonable cost. We anchor them properly for wind—carports become kites in hurricanes if not engineered correctly.

Commercial metal building construction requires engineering and permits. We work with manufacturers who provide stamped engineering drawings that meet parish building department requirements. Foundation design varies by soil conditions; slab-on-grade works in some locations, pier-and-beam in others.

Insulation and ventilation determine whether a metal building stays tolerable in summer. Uninsulated metal buildings are ovens. We install fiberglass or spray-foam insulation, add ridge and soffit vents, and sometimes include exhaust fans for active ventilation.

Concrete floors usually accompany metal buildings. We pour a four- to six-inch slab, add wire mesh reinforcement, slope it for drainage, and install a vapor barrier under the slab. Some clients want drains for wash-down capability or epoxy coatings for easier cleaning.

New Construction Contractor

Custom home building in Acadiana requires an understanding of local building science. What works in Texas or Mississippi doesn’t always work here. Foundation choices depend on soil conditions. Moisture management requires different strategies than drier climates. Energy efficiency means dealing with humidity as much as temperature.

Pier-and-beam foundations work well in areas with poor soil or in flood zones. The home sits elevated above ground level, which helps with drainage and provides insurance benefits in flood-prone areas. Crawl spaces need proper ventilation and vapor barriers to prevent moisture problems.

Slab foundations are common in newer developments where soil conditions allow. Properly engineered slabs resist cracking from soil movement. We install termite protection, vapor barriers, and insulation around slab perimeters. The slab needs to be high enough above grade to prevent water intrusion.

Energy-efficient construction goes beyond insulation. We install house wraps and air barriers to prevent moisture intrusion. HVAC systems need to be sized for humidity removal, not just cooling. Proper ventilation in bathrooms and kitchens removes moisture at the source.

We built a custom home in Scott last year on challenging soil. Geotechnical testing showed expansive clay that would shift. We designed a post-tension slab foundation to resist cracking, installed French drains along the perimeter, and used soil stabilization beneath the slab. Two years later, not a crack anywhere.

Residential and room additions require matching materials and methods with the existing construction. You can’t just slap an addition onto a house without considering how it ties into the existing structure, how the foundations interact, and whether the existing HVAC can handle the additional load.

Flood elevation compliance matters in many parts of Acadiana. New construction in flood zones must be elevated above the base flood elevation. This affects foundation design, utility connections, and access. We work with surveyors and engineers to meet FEMA requirements.

Threat Mitigation

Commercial security construction has grown since 2020. Business owners in Lafayette, New Iberia, and across Acadiana want facilities that deter crime and protect assets.

Perimeter security starts at property lines. Bollards prevent vehicle intrusion. Anti-ram barriers protect storefronts. Reinforced fencing creates secure boundaries. We work with security consultants to design systems that balance security, aesthetics, and accessibility.

A medical facility in Lafayette needed perimeter hardening after vehicles repeatedly crashed into its building. We installed decorative bollards that look like architectural elements but will stop a truck. The building is protected, and the bollards match the landscape design.

Structural hardening means reinforcing vulnerable points. Bullet-resistant glass in windows and doors. Reinforced door frames that resist forced entry. Security vestibules with dual access control. These modifications need to comply with fire codes and accessibility requirements.

Safe rooms and secure storage areas require specific construction. Reinforced walls using concrete, steel, or composite materials. Blast-resistant doors with proper anchoring. Access control systems are integrated into construction. Proper ventilation and life safety systems.

Banks, jewelry stores, pharmacies, and facilities handling valuable assets need secure spaces. We build vault rooms, secure storage areas, and protected spaces in accordance with industry standards. The construction integrates with electronic security but provides physical protection as the primary layer.

Materials and Partnerships

We buy from regional suppliers when possible. Home Depot, local lumber yards, and specialty suppliers know our quality standards and stock materials we specify. Local purchasing means faster delivery and better support when we need specific items quickly.

We work with trusted manufacturers known for quality and reliability. GAF roofing, James Hardie fiber cement siding, and Trex composite decking are brands we use regularly on projects throughout Acadiana. These manufacturers stand behind their products with strong warranties that give you additional protection and peace of mind.

Service Area

We serve Lafayette, New Iberia, Broussard, Youngsville, Carencro, Scott, Rayne, Crowley, Opelousas, Eunice, Abbeville, and the entire Acadiana region. Our crews know the area, understand local building challenges, and can respond quickly to emergencies or project needs.

Three generations of building in South Louisiana taught us that Acadiana requires contractors who understand the climate, the soil, the storms, and the culture. We’re not here to reinvent construction; Aivast Construction is here to build things that last in a place that tests everything.

Emergency Response and Storm Services

Louisiana weather doesn’t follow regular business hours. When trees fall through roofs at midnight, or businesses flood during weekend storms, you need an immediate response.

We maintain emergency crews ready for after-hours calls. Our project managers live throughout Lafayette in neighborhoods like the Saint Streets, River Ranch, and areas near the University of Louisiana. Someone is always within 20 minutes of your property. We board windows, tarp roofs, extract water, and secure buildings until permanent repairs begin.

After major storms, we prioritize emergency services, then systematically work through repair backlogs. Some contractors leave town when big storms hit. We stay because our families live here too.

Insurance Claims and Documentation

Insurance paperwork stresses people during already difficult situations. We handle documentation so you can focus on getting life back to normal.

Our estimators document damage thoroughly with photos, measurements, and detailed descriptions. We write estimates matching insurance company formats and replacement cost calculations. We’ve worked with every major carrier operating in Louisiana. Most adjusters recognize our company name and know our estimates are accurate.

We supplement initial estimates when necessary. Insurance companies often miss hidden damage or undervalue necessary repairs. We document additional issues, provide supporting evidence, and negotiate fair settlements that cover all necessary work.

Licensed, Bonded, and Insured

We maintain all required Louisiana contractor licenses and carry liability insurance that exceeds the minimum requirements. Our workers’ compensation coverage protects our employees and shields you from liability if accidents occur on your property.

Permits matter. Some contractors skip them to save time or avoid inspections. That creates serious problems when you sell property or file insurance claims. We obtain the proper permits for every job that requires them and coordinate inspection schedules with parish offices.

Materials and Partnerships

We buy from regional suppliers when possible. Home Depot, local lumber yards, and specialty suppliers know our quality standards and stock materials we specify. Local purchasing means faster delivery and better support when we need specific items quickly.

We work with trusted manufacturers known for quality and reliability. GAF roofing, James Hardie fiber cement siding, and Trex composite decking are brands we use regularly on projects throughout Lafayette. These manufacturers stand behind their products with strong warranties that give you additional protection and peace of mind.

Project Management and Communication

Every project gets a dedicated project manager from estimate through completion. Their cell number goes on your contract. Call them directly with questions, schedule concerns, or change requests.

We provide regular updates on larger projects. You’ll receive photos, task completion lists, upcoming work schedules, and notice of any issues requiring decisions. Surprises slow projects and create conflict. We communicate early and often to prevent problems.

Change orders happen on most projects. You see work in progress and decide you want something different or better. We price changes fairly, document them in writing, adjust schedules accordingly, and never surprise you with unexpected bills at final payment.

Our Commitment to Lafayette

Lafayette has supported our business for 15 years. We’ve hired local workers, purchased from local suppliers, and raised families here. When schools need sponsors, nonprofits need support, or community projects need help, we contribute.

We’ve built homes in Grand Pointe and Couret Farms. We’ve repaired storm damage to businesses along Johnston Street. We’ve worked on projects near Vermilionville and the University of Louisiana campus. This community is our home, and we treat every project as if we were working on our own property.

Getting Started

Most projects start with a phone call or online contact. Tell us what you need, and we’ll schedule a property visit. Estimates are free. We measure carefully, discuss your goals and budget, and provide detailed written proposals.

Small projects can start within days. Larger jobs require permits, material ordering, and crew scheduling, which typically takes one to three weeks. We’re honest about schedules and never promise timelines we can’t meet.

Emergency work starts immediately. Storm damage, flooding, or security concerns get a same-day response. We mobilize crews fast when situations require urgent action.

Ready to Discuss Your Project?

Whether you need emergency water damage restoration, roof replacement, a new outdoor kitchen, commercial security upgrades, or complete new construction, we bring local expertise and proven quality to every job.

Call us today to discuss your project. We’ll answer questions, provide straight information about costs and schedules, and help you make decisions that protect your Lafayette property for years to come.

Aivast Construction Lafayette, LA – Your Partner for Quality Construction in the Heart of Cajun Country.

Aivast Construction is here to help, proudly serving Lafayette, New Iberia, Broussard, Youngsville, Carencro, Scott, Rayne, Crowley, Opelousas, Eunice, Abbeville, and the entire Acadiana region.